Plastic Biofilters

Closed modular plastic biofilters | Technopolymer grids and feet

Ecoimpianti can supply plastic closed modular biofilters.

iofilters made by Ecoimpianti consist of a parallelepiped or cylindrical tank. The parallelepiped tank is made of self-supporting corrugated PP. The cylindrical tank is made of modular PP (moplen) elements.

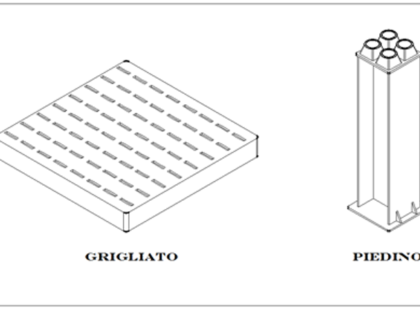

As Components, Ecoimpianti can also supply only glass-fibre reinforced technopolymer grids and/or feet needed to support the biofilter filtering material. We also provide the Surface Irrigation System.

Grids and feet can also be supplied by Ecoimpianti to the customer for large open biofilters.

Description of a Biofiltration Plant Type

Biofilters can be closed with a spot emission or open with an emission along the entire filter surface.

The biofilter essentially consists of a layer of filter material that lies on a bed of grids that are supported by feet, both technopolymer. Under this plenum, the conditions are created to ensure an even distribution and proper low-speed passage of the air to be treated.

The supporting surface of the filter material consists of modular grid tiles (500 x 500 mm) made of glass-fibre reinforced polypropylene and H-shaped supports also made of glass-fibre reinforced polypropylene with a height of 300 mm / 500 mm. The maximum design static load of such flooring is 3000 kg/sqm.

The flooring that the H-brackets will rest on should normally have a minimum slope in order to best channel the percolating water through the drainage pipes. The air to be treated will be captured and conveyed through pipes (galvanised steel or stainless steel or polypropylene or PVC), using fans and sent if necessary first to pre-treatment and then to the biofilter plenum.

The biofilter is completed with a humidification system where nutrients are dosed if necessary, consisting of a network of sprayers and the various command and control equipment.

- Biofiltration - Biofilter (link to information)

- S.O.V. Purification (link to information)

Specific expertise in plastics processing

Many years of experience and technical knowledge in the field of plastics processing. We process any plastic material required including the most common and popular PP, PE, PVC, PPS, PVDF. Based on the physical, chemical and mechanical properties required by the project, we provide assistance in selecting the most suitable plastic material.